Upgraded sludge treatment scheme! Qingdao Yimei Environmental Engineering Co., Ltd. complete equipment started to Uruguay Montevideo

Time of issue:

2025-08-04

August 4, 2025-Today, a sludge deep treatment system consisting of screw conveyor, spiral dewatering machine, intelligent dosing tank and internal water microfilter set sail from a Chinese port to help upgrade the municipal sewage treatment plant in Montevideo, capital of Uruguay.

Technical highlights of core equipment

equipment | Technological innovation points | Customer value |

screw conveyer | 304 stainless steel U-shaped groove + shaftless spiral design | Anti-wrapping, conveying efficiency increased by 40%, energy consumption <2.2kW |

Lime dewatering machine | Dynamic ring gap 0.8mm + hydraulic pressure regulating system | The moisture content of clay cake is less than or equal to 80%, and it can be cleaned automatically to prevent blockage |

Intelligent dosing bucket | PE rotomolding integrated molding + metering pump linkage PLC | Resistant to strong acid and alkali, the dosage accuracy error is ±3% |

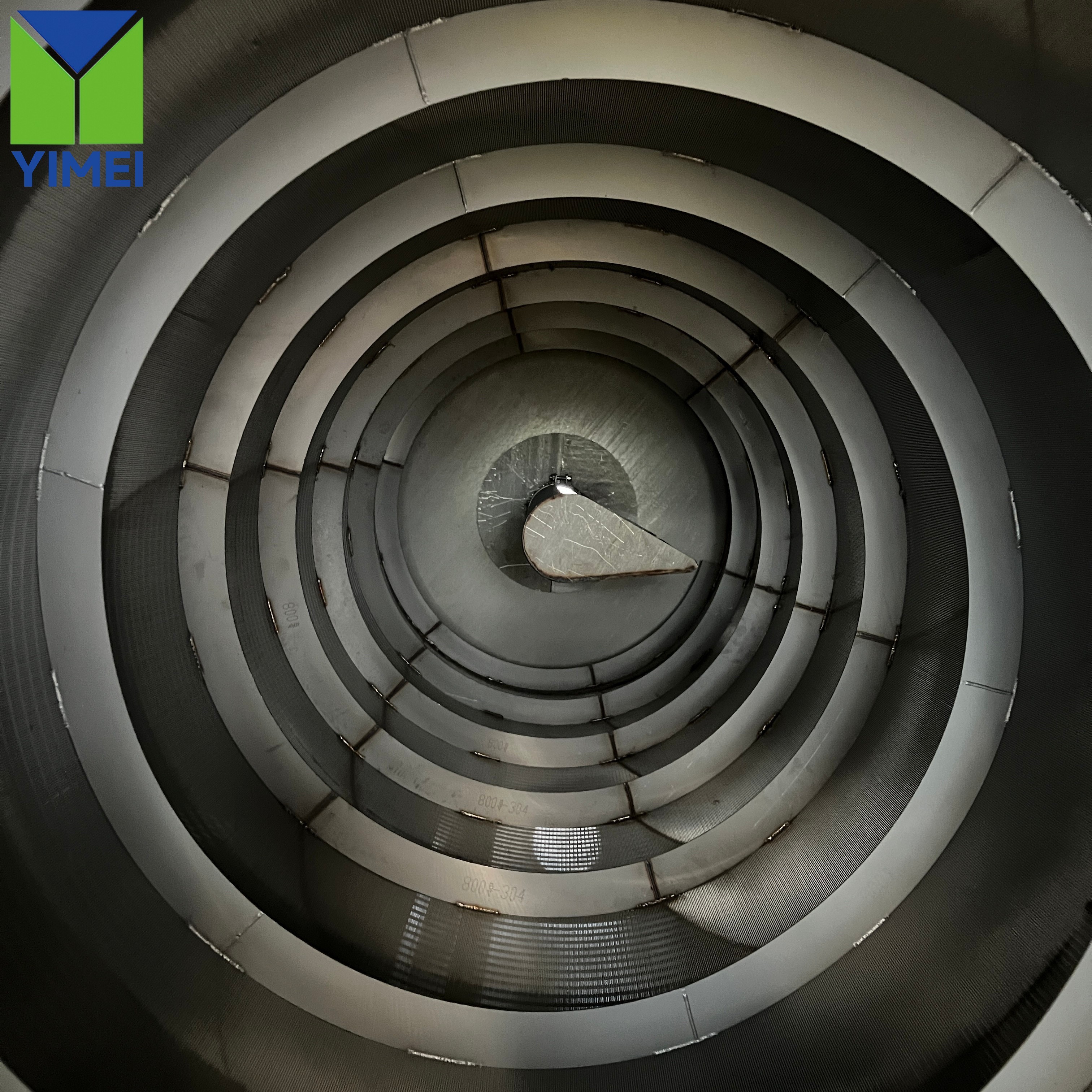

Internal water inlet microfilter | 316L stainless steel filter screen + internal inlet and outlet mode (precision 50μm) | The interception rate is more than 92%, and the backflow water is saved by 35% |

System integration advantage

▶ Closed-loop treatment of sludge reduction

` Screw conveyor ` Collection of primary sedimentation tank sludge ` Microfiltration machine ` Fine screening ` PAM treatment bucket ` High pressure dewatering to reduce the volume of sludge by 70%

▶ Intelligent control core

-Cloud monitoring of dosage, dehydration pressure and flow parameters

-Automatic SMS alarm for abnormal status (Spanish support)

-Remote diagnosis reduces field maintenance costs by 30%

▶ South American environmental adaptation design

-Equipment bracket carbon steel hot galvanized (resistant to Marine climate corrosion)

-Electrical cabinet IP65 protection class (moisture and dustproof)

-Modular quick installation structure (save 15 days of installation time)

Project background and impact

The municipal sewage treatment plant has a daily capacity of 30,000 tons, and the original sludge disposal cost accounts for 45% of the operating costs. The Chinese intelligent manufacturing solution introduced this time will be implemented through:

1. Energy saving: the total power of the system is less than or equal to 18.5kW

2. Resource recovery: The dehydrated sludge cake can be used as garden substrate soil

3. Land optimization: The equipment group occupies only 80㎡ (60% less than the traditional scheme)

Assist them to achieve the latest Agricultural Sludge Standards of the Ministry of Environment of Uruguay (Resolution 1234/2024)

Latest blog

No. 386, Haibin 5th Road, Huangdao District, Qingdao, Shandong, China